Gas safety isn’t just an industrial concern – it plays a role in residential, commercial, and HVAC environments as well. Whether it’s a technician working in a confined space, a property owner ensuring safe heating, or a business maintaining compliance, knowing what gases are present in the air can save lives. That’s where a 4-gas monitor comes into play.

This article breaks down what a 4-gas monitor is, the gases it can detect, and why gas monitoring is so valuable in everyday and professional situations. By the end, you’ll understand how these detectors work, why calibration and cleaning matter, and how proper use supports repair and installation tasks in HVAC and electrical services like those offered by KSR HVAC & Electrical, LLC.

What is a 4-Gas Monitor?

A 4-gas monitor is a portable gas meter designed to measure levels of hazardous gases in the air. The monitor is designed with multiple sensors to detect the presence of gases simultaneously and trigger an alarm when unsafe concentrations are reached.

For technicians, this device is a shield against invisible threats. It provides accurate readings of gas concentration in confined spaces, alerting workers before gas exposure causes harm.

These detectors are commonly used in:

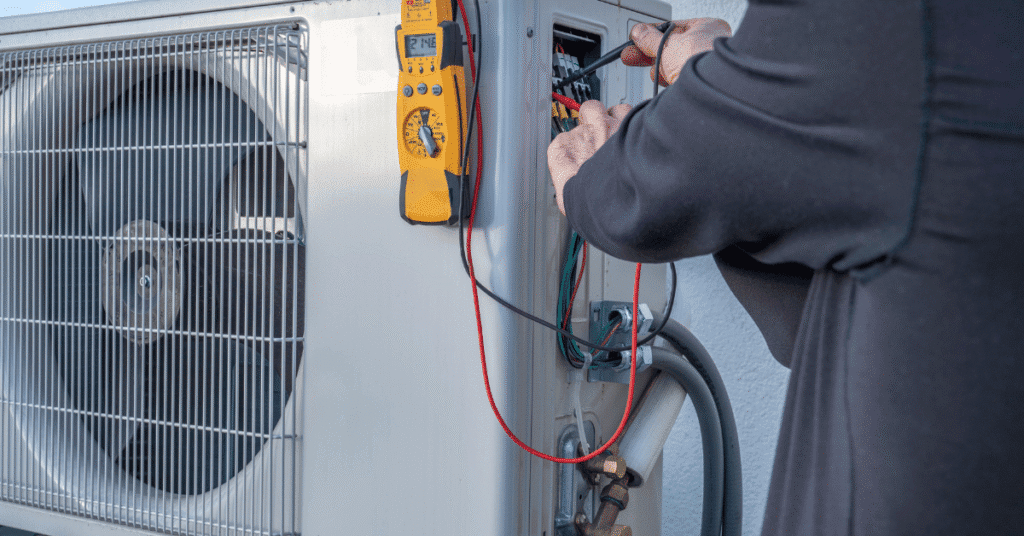

- HVAC cleaning, maintenance, and repair work

- Electrical installation inside enclosed spaces

- Construction and industrial projects

- Oil and gas sites

- Wastewater and sewer systems

No matter the application, the goal of gas detection equipment is to protect both workers and property occupants from hazardous gases.

The Four Gases Detected by a 4-Gas Monitor

The name says it all – a 4-gas monitor detects four main gases that pose serious safety risks.

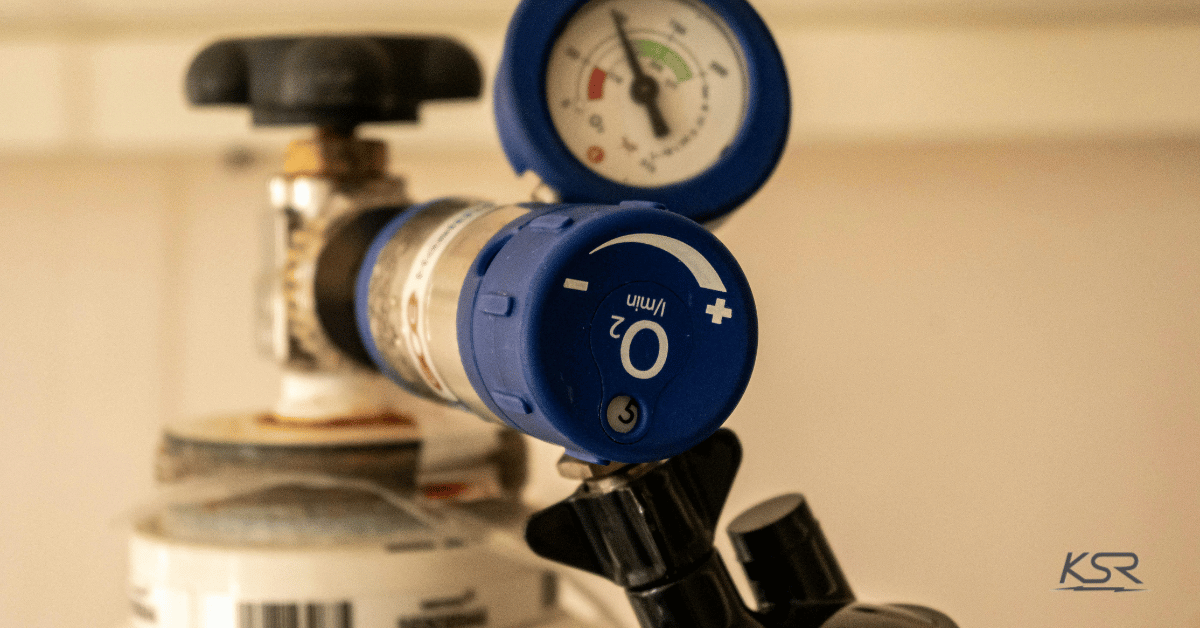

Oxygen (O₂)

- Air normally contains about 20.9% oxygen.

- If oxygen level drops below 19.5%, symptoms include dizziness and loss of consciousness.

- High O₂ levels can increase fire risks.

- Monitoring oxygen concentration is critical in enclosed spaces like basements or crawlspaces during installation or repair.

Carbon Monoxide (CO)

- Produced by natural gas appliances like furnaces, water heaters, and generators.

- Known as an odorless gas and silent killer.

- Exposure can cause nausea, headaches, or even death.

- Carbon monoxide detection is vital for safe HVAC cleaning and gas monitoring.

Hydrogen Sulfide (H₂S)

- Found in sewers, septic systems, and some building processes.

- Has a rotten egg smell at low concentrations but becomes undetectable at high levels.

- Hydrogen sulfide can cause severe respiratory distress or unconsciousness.

- Monitoring hydrogen is essential for occupational safety and health in confined spaces.

Combustible Gases (LEL – Lower Explosive Limit)

- Includes methane, propane, and other combustible gases.

- The gas detector alerts when gases reach explosive levels.

- Crucial for technicians working with installation and repair of fuel-burning systems.

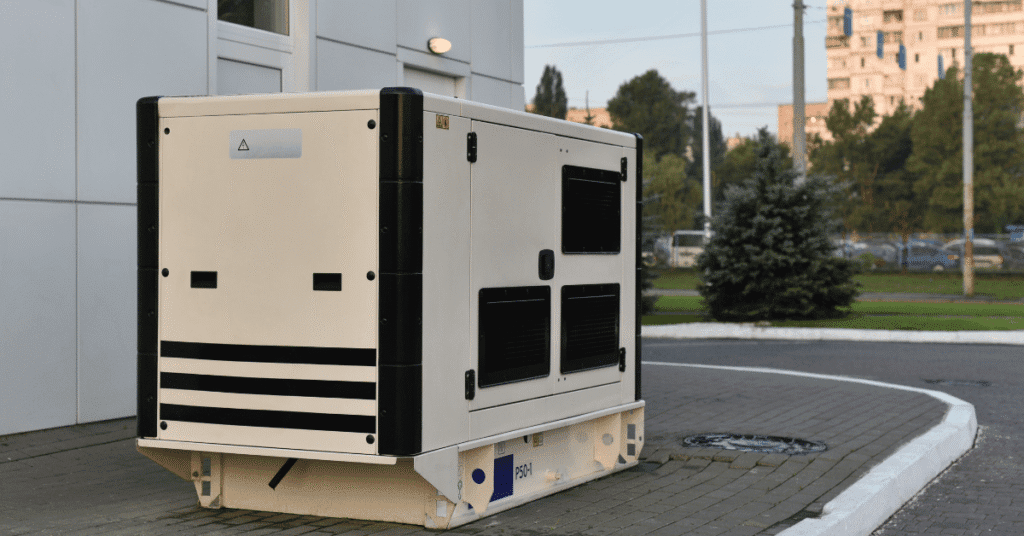

- Detecting combustible gas ensures safety during generator and HVAC work.

Why Are 4-Gas Monitors Important for Safety?

Most gases cannot be seen, smelled, or tasted. A 4-gas monitor detect system is intended to detect hazards early.

- Prevents accidents in confined or enclosed spaces

- Ensures compliance with Occupational Safety and Health Administration standards

- Protects worker health and safety through early detection and alarms

- Provides peace of mind for property owners during HVAC installation and cleaning services

Applications of 4-Gas Monitors in HVAC & Electrical Work

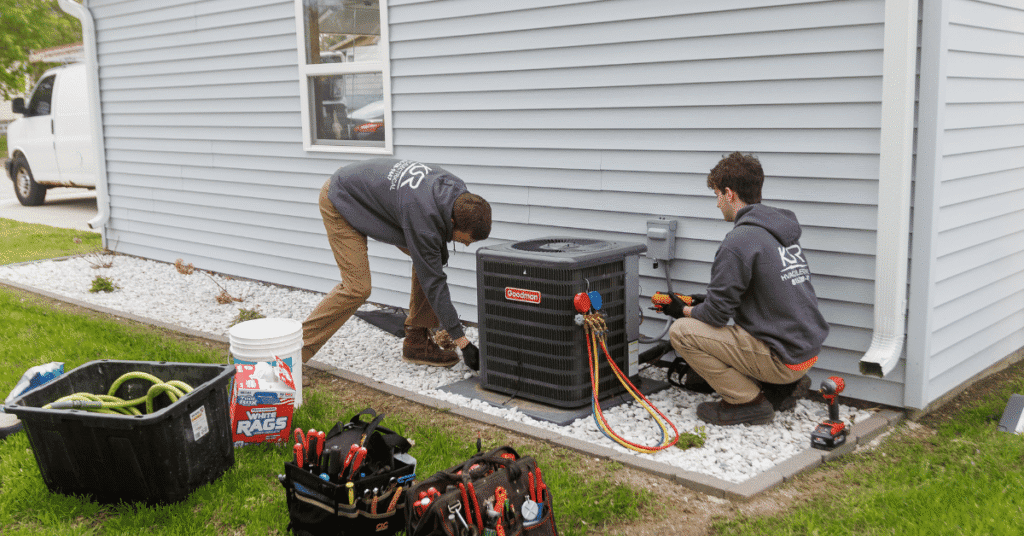

At KSR HVAC & Electrical, our technicians use multi-gas monitors as part of everyday service:

- Gas Leak Detection – Detects leaks in furnaces, boilers, or propane heaters.

- Confined Space Safety – Ensures crawlspaces and mechanical rooms have safe gas levels before entry.

- Generator Installations – Protects against CO and combustible gases during setup.

- Indoor Air Quality – Identifies various gases affecting health and comfort.

Using a 4-gas monitor to detect multiple gases ensures reliable repair, installation, and long-term safety.

How to Properly Use and Maintain a 4-Gas Monitor

A gas monitor is only reliable with correct calibration and maintenance.

Steps for Use

- Power on before entering confined areas.

- Perform a bump test with calibration gas to verify sensors.

- Carry the monitor in your breathing zone.

- Exit immediately if the alarm sounds.

Maintenance

- Regularly calibrate sensors to calibration gas.

- Replace batteries and damaged sensors.

- Keep detectors clean to ensure accurate readings.

- Follow the manufacturer’s instructions for proper calibration.

Choosing the Right 4-Gas Monitor

When selecting a gas monitoring device, consider:

- Loud and visible alarm systems

- Long-lasting batteries

- Accurate readings under various gas concentrations

- Durable sensor technology for multiple gases

- Data logging for occupational safety records

Professional-grade detectors are best for contractors, while homeowners may choose single-gas detectors for CO monitoring.

KSR HVAC & Electrical’s Commitment to Safety

Our technicians are trained to use 4-gas monitors in daily HVAC and electrical work. Whether cleaning, repair, or installation of systems, our team values occupational safety and well-being. Using professional gas detection equipment ensures accurate readings and safe environments for every project.

Conclusion

A 4-gas monitor is a device that detects four main gases: oxygen, carbon monoxide, hydrogen sulfide, and combustible gases. By using a gas detector properly, technicians protect themselves and others from dangerous gas exposure in confined and enclosed spaces. Whether it’s HVAC cleaning, generator installation, or industrial gas monitoring, these detectors are critical for occupational safety and health.

Frequently Asked Questions

How often should a 4-gas monitor be calibrated?

Most recommend every 30 days, but always follow the manufacturer’s instructions.

Can a 4-gas monitor detect more than four gases?

Yes, advanced multi-gas detectors exist, but standard monitors focus on four main gases.

Do homeowners need a 4-gas monitor?

Not always, but a carbon monoxide detector is essential for every home.